Vertical: Airports, logistics

Application: Automated inventory management, drone-based stocktaking, warehouse safety monitoring

Ecosystem: Spark New Zealand, Ericsson, Cypher Robotics

Private Network: 5G

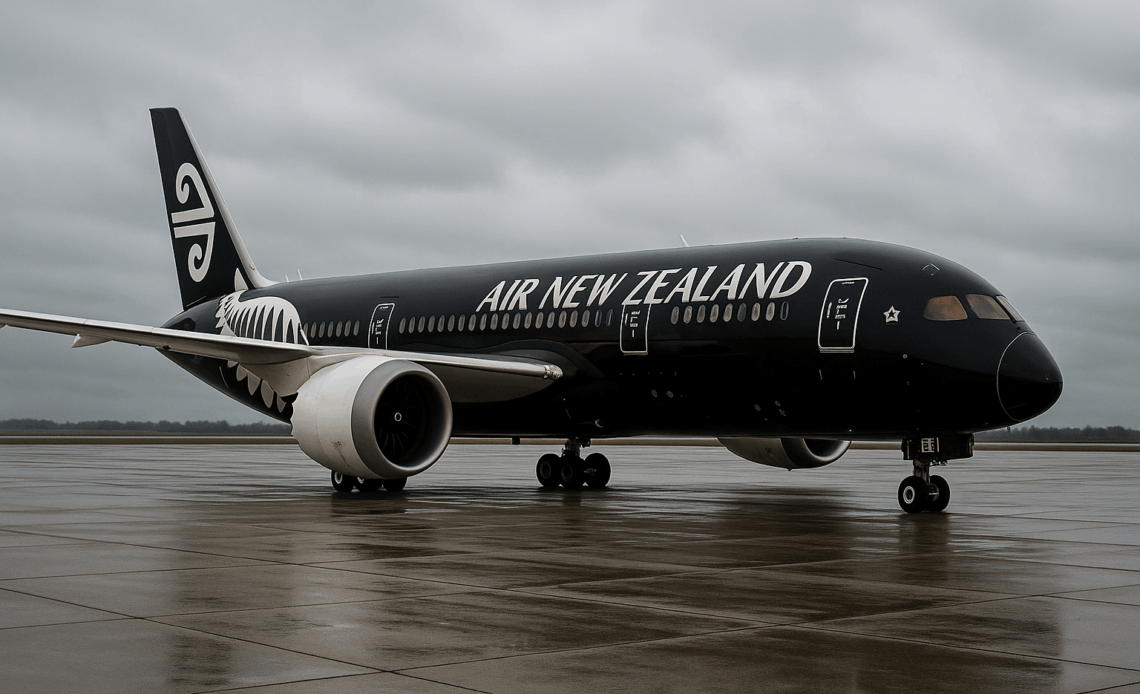

Spark and Air New Zealand have deployed New Zealand’s first private 5G network for enterprise applications at Auckland Airport’s logistics warehouse. The network brings advanced connectivity to a complex industrial environment where traditional Wi-Fi struggles with reliable coverage.

The 5,000 square meter facility houses thousands of items from aircraft spare parts to passenger amenities. Previously, the warehouse relied on manual stocktaking twice annually, requiring staff to climb heights up to 15 meters. This labor-intensive approach posed safety risks and provided limited inventory visibility.

Built on Ericsson’s private 5G platform, the network enables real-time communication where high shelving and narrow aisles challenge wireless connectivity. The technology supports Captis, an autonomous mobile robot with integrated drone from Canadian company Cypher Robotics. The system scans barcodes while transmitting data instantly to a dedicated application.

“Air New Zealand is always looking for innovative ways to improve operational efficiency and deliver smarter, safer, and more seamless experiences for our people and customers,” said Nikhil Ravishankar, Air New Zealand’s Chief Digital Officer. “Partnering with Spark to launch New Zealand’s first private 5G network for business is a demonstration of that commitment.”

The automated system performs inventory counts every 10 days, replacing biannual manual counts. This provides daily stock visibility, streamlining decision-making and improving inventory accuracy while eliminating dangerous height work for employees.

Spark and Air New Zealand are exploring additional applications, including 5G-connected cameras monitoring personal protective equipment compliance near active vehicles. The system would analyze footage in real-time using artificial intelligence to enhance safety protocols.

“This isn’t just an airline issue – businesses across various industries with intricate supply chains stand to gain from increased automation, which can boost productivity, enhance customer experiences, and create safer working environments,” explained Mark Beder, Spark’s Customer Director for Enterprise and Government.

The collected data could eventually power a digital twin of the warehouse, enabling scenario simulation, layout optimization, and predictive maintenance. “We are an industry that’s really struggling to get back on our feet post-Covid,” Ravishankar noted, emphasizing that better supply chain management affects flight scheduling.

“This warehouse is a very complex radio environment,” said Ian Ross, Ericsson’s head of enterprise for private networks. “Wi-Fi has struggles providing good signal quality in the depths of aisles, particularly with rack height, where 5G is optimised for this environment.”