Covid has been a rude awakening for supply chain managers. Successive shocks have roiled supply planning—delays in deliveries, adverse weather events, blockage in Suez Canal, port congestion, empty shelves in retail stores, and more. No end to the disarray is in sight as supply chains need a redesign to cope with disruptions.

The sole objective of supply chains has been to keep costs low and keep goods flowing for average volatility in the business environment. However, while wild swings in demand with bull-whip effects have been endemic in supply chains, nothing prepared them for the demand swings with every strain of Covid or lockdowns. According to a report by Capgemini Research Institute, 69 percent of organizations in its survey found it hard to adjust production capacity in response to fluctuating demand.

Creating resilient supply chains

Real-time information sharing among manufacturers, shippers, and logistics companies is conspicuous by its absence. Managers have not had the infrastructure to aggregate data of the movement of inventory flow and means of transportation, whether trucks, ships, or trains. Furthermore, partners were unwilling to share data to gain visibility into supply chains end-to-end.

Supply chains are undergoing wrenching restructuring to embed technology to monitor the time and location of goods across the supply chain. They want to anticipate potential repercussions of events at any stage of the journey on the eventual outcomes.

The enormity of the task of restructuring supply chains has had a sobering effect on supply chain managers. They recognize they need a resilient supply chain that remains on course whatever the shock it endures. They would need to gather live data from manufacturing plants, warehouses, and transportation assets, with sensors and computer vision. They now realize they need to share data to assess the demand and supply situation and remedy any shortfall or excess. 5G private networks will contribute the reliability and low latency to process so much data.

Visibility and real-time data

There is a widespread realization in boards of companies that a radical shift will be needed to cope with future shocks to the supply chain (66%). They can mitigate risk by rapid simulation of scenarios.

A vast range of variables impact supply chains that spreadsheets cannot parse. Instead, digital twins process the data (84 percent) faster and visualize it. In addition, it provides a dynamic view of the delivery landscape, which pinpoints the impact any one component, such as the introduction of a new product or vendor, will have on demand and supply. Renault is one of the early adopters of digital twins to manage risk in supply chains.

Attitudes towards the importance of real-time data and visibility in the supply chain have advanced tremendously. According to the 2022 report of 3PLs (Third-Party Logistics companies), logistics companies seek to improve real-time decision-making (57%) by investing in Internet of Things technology. Among shippers, the corresponding figure is 53 percent. 3PLs also recognize that exception management is a competitive differentiator (57%). However, the adoption is currently modest, with only 53 percent able to provide real-time data in 50 percent of their supply chain services.

The environment for information sharing to make analytics feasible is encouraging. A majority, 75 percent of 3PLs and 49 percent of shippers, agreed they would collaborate with other companies, even competitors, to improve logistics service improvements.

Most shippers (52%) and 3PLs (63%) recognize that 5G technology is either moderately or critically crucial for operational efficiency and flexibility. For example, smart glasses in the 5G environment read labels and bar code numbers, automatically speeding up the movement of goods.

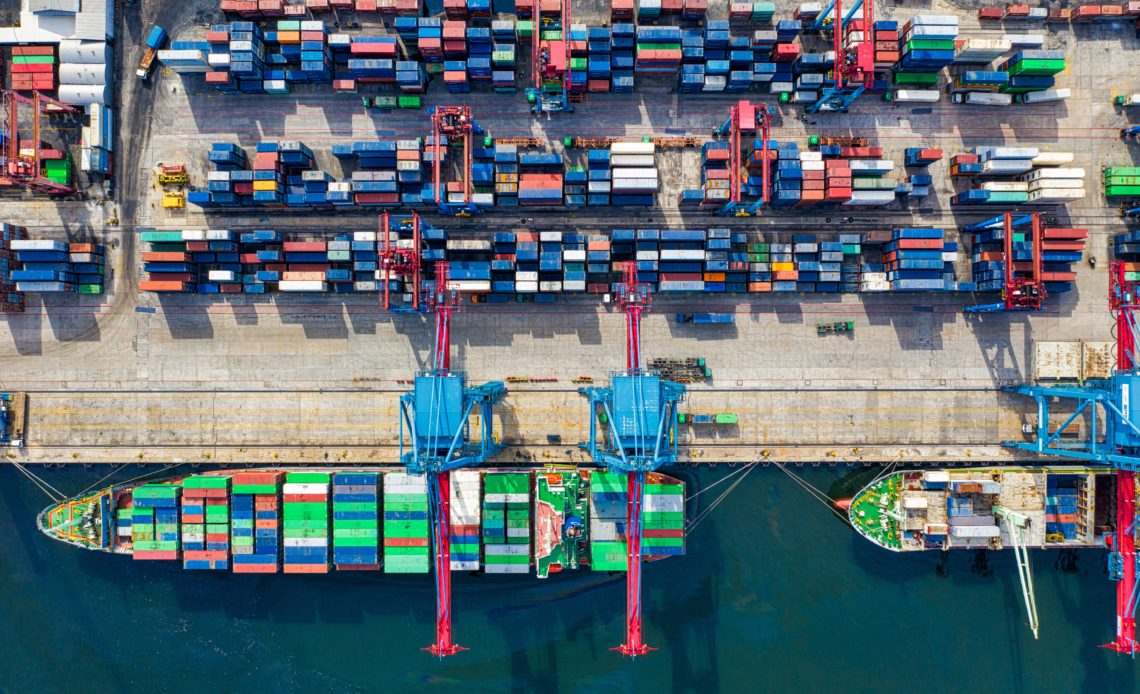

Shipping Delays

The coordination of vessel arrivals and availability of berths at seaports was a long-standing challenge, primarily because of the uncertainty created by unavoidable weather conditions. Port congestion was chronic before the Covid crisis, which aggravated matters with the inability to control the pace of operations at ports. Real-time information of exceptions is especially urgent to make changes to avoid congestion. The average time it takes to get a package from Asia to the US has increased by 43% since September of last year.

Private networks and resilient supply chains

The Intelligent Crossroads Network, currently confined to Utah, has built a private network for an intelligent AI-augmented supply chain that senses and adapts to unanticipated shocks.

At the Port of Livorno in Italy, Ericsson built a private network to optimize general cargo flow with objects of varying dimensions enclosed in non-standard packages. Dynamic range cameras identify the objects and their sizes and locations in the storage area mapped on a digital twin of the port. The drivers of vehicles and forklifts receive the port map on their Occulus devices, and lasers direct them to the cargo they expect to pick up; the inventory flows unimpeded due to the removal of the guesswork in finding the shipment.

Hanhaa is a parcel tracking company that uses sensors embedded in its Parcel Live device to provide data on the location and movement. Additionally, it collects data on the damage to packages and environmental conditions such as humidity and temperature. Hanhaa sells the data to logistics companies who gain visibility into the flow of goods and their exposure to risks such as damage. An associated company, Hanhaa XG, provides a private mobile network to stream the data securely.

Conclusion

The old world view of supply chains was moving physical goods from one end to another. They were stored in physical spaces to be driven by physical transportation assets. Covid-19 has torn the veil to see the data in the movement of these goods and X-Reality to visualize it. Digital twins uncover the hidden opportunities to speed up the movement of goods. Private networks securely bring together the data in real-time to make decisions on more efficient ways to move them from one end to another.

Learn more about Private LTE Network